FFF Friday: 3D Printing Resources for Beginners

Newbies, this one’s for you!

3D printing has been rising in popularity in the past few years. It’s begun to show up in headlines ranging from “3D printing is OSSIM -- it makes prosthetics!” to “3D printing is EVIL -- it makes guns!”. However, the practice of creating a 3-dimensional physical object from a digital model is still a new concept to many people. Maybe you’ve vaguely heard of it but don’t necessarily understand the mechanics of it. Maybe you’re interested in learning but don’t know where to start. Or you know a little and want to take it further. Whatever your background, we all have to start somewhere, so for today’s FFF Friday, I’ve put together a few resources for newcomers to the wide world of 3D printing.

This isn’t meant to be an exhaustive list by any means, just a brief roundup of links to point you in the right direction. Oh, and just as a standard disclaimer: nobody linked in this post -- or any others -- is paying or bribing me to promote them. :-)

When I refer to 3D printing, I’m usually talking about fused filament fabrication (FFF), also called fused deposition modeling (FDM), though that’s a trademarked term. This is the kind that involves squeezing filament through a heated nozzle and laying it down one layer at a time. Other types of 3D printing deploy different methods of forming the 3D object, such as powder or [frickin’] lasers; FFF is the most widely used among hobbyists and the easiest to access. If you have 15 minutes to spare, Lisa Harouni’s TED Talk gives a good intro to the different types of 3D printing and some of the amazing things it can do.

The software: One of the best places to start may be simply playing around with some of the software used in 3D printing. 3D modeling is typically done using a computer aided design (CAD) program like OpenSCAD or SolidWorks, or a computer graphics program like Blender or SketchUp (to name just a few of each). Software costs run the gamut from free and open source to “you want me to pay HOW much?!” Regardless of program, Teh Interwebs has many tutorials and docs for learning your way around the software.

The hardware: It’s remarkable how much 3D printers have come down in price recently: you can now buy one for as little as a few hundred dollars. New printers are constantly being developed -- it seems like there are always a few on Kickstarter at any given time -- with various features, but they usually share the same core components: nozzles for filament, a heated build platform, controls for temperature and alignment, connector to a computer, etc. Some come plug-and-play, while others require some assembly. One of the most innovative developments, IMHO, in 3D printing is the RepRap Project’s introduction of printers that are actually self-replicating: you can print the parts to assemble your own printer!

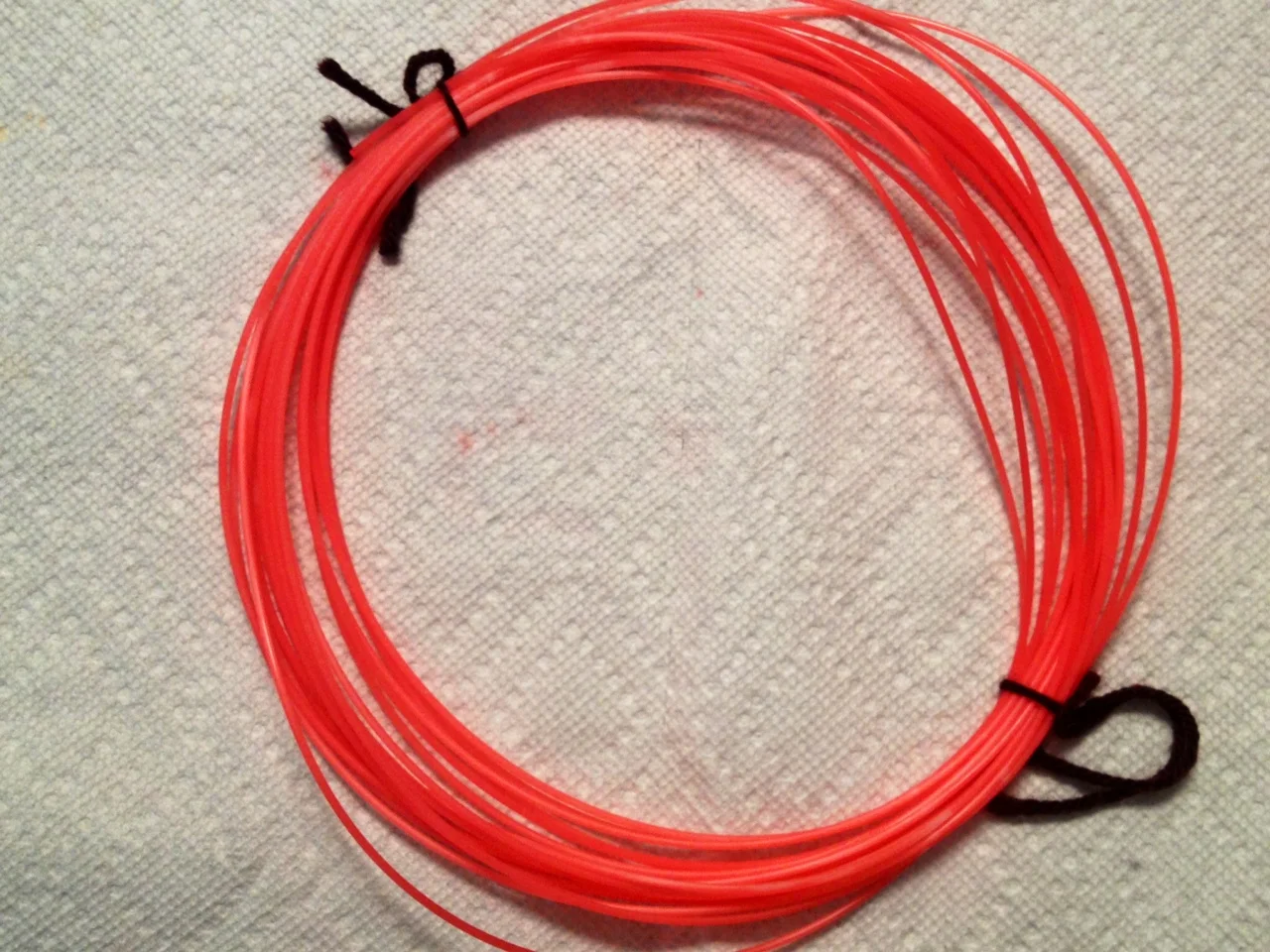

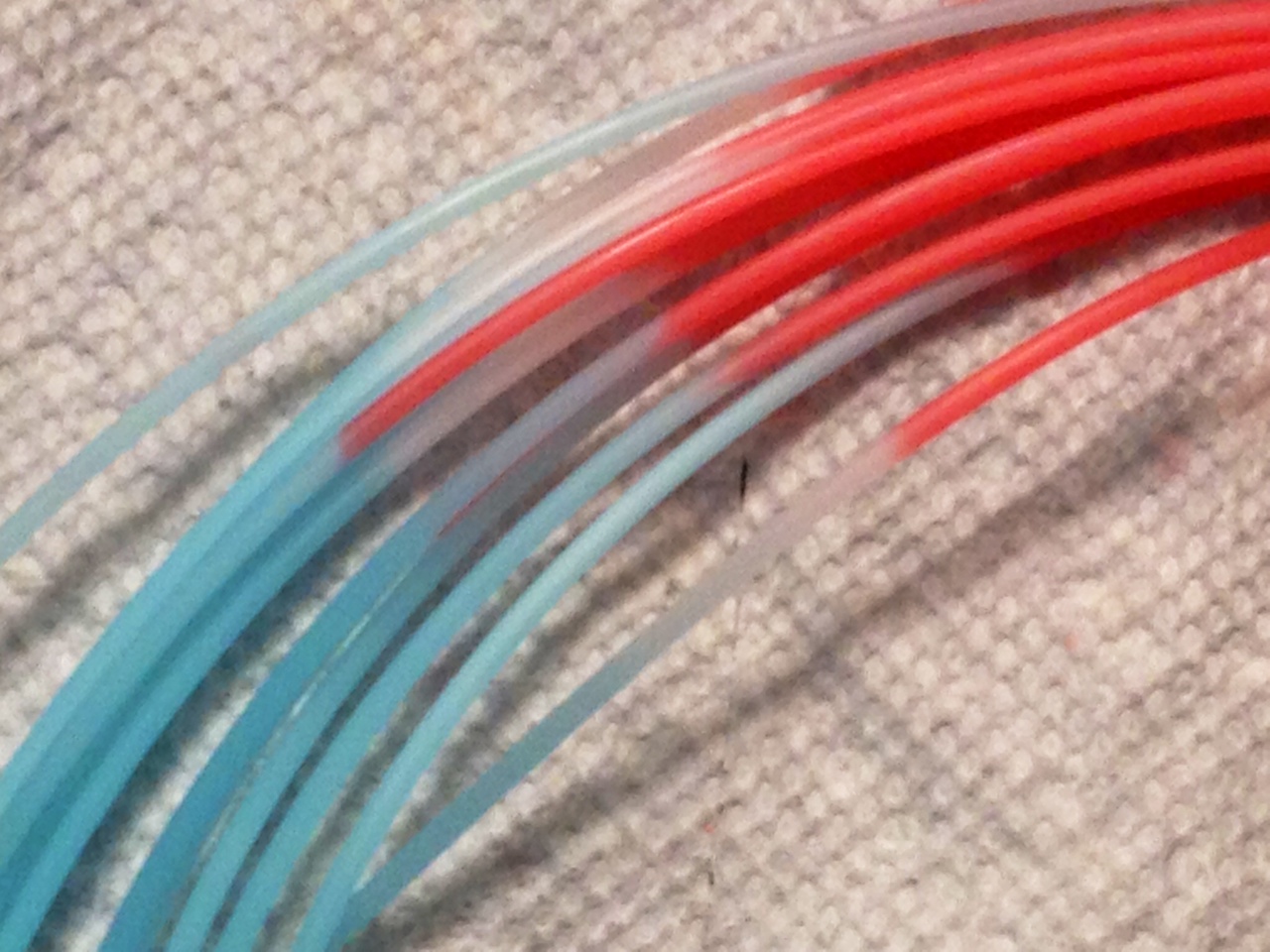

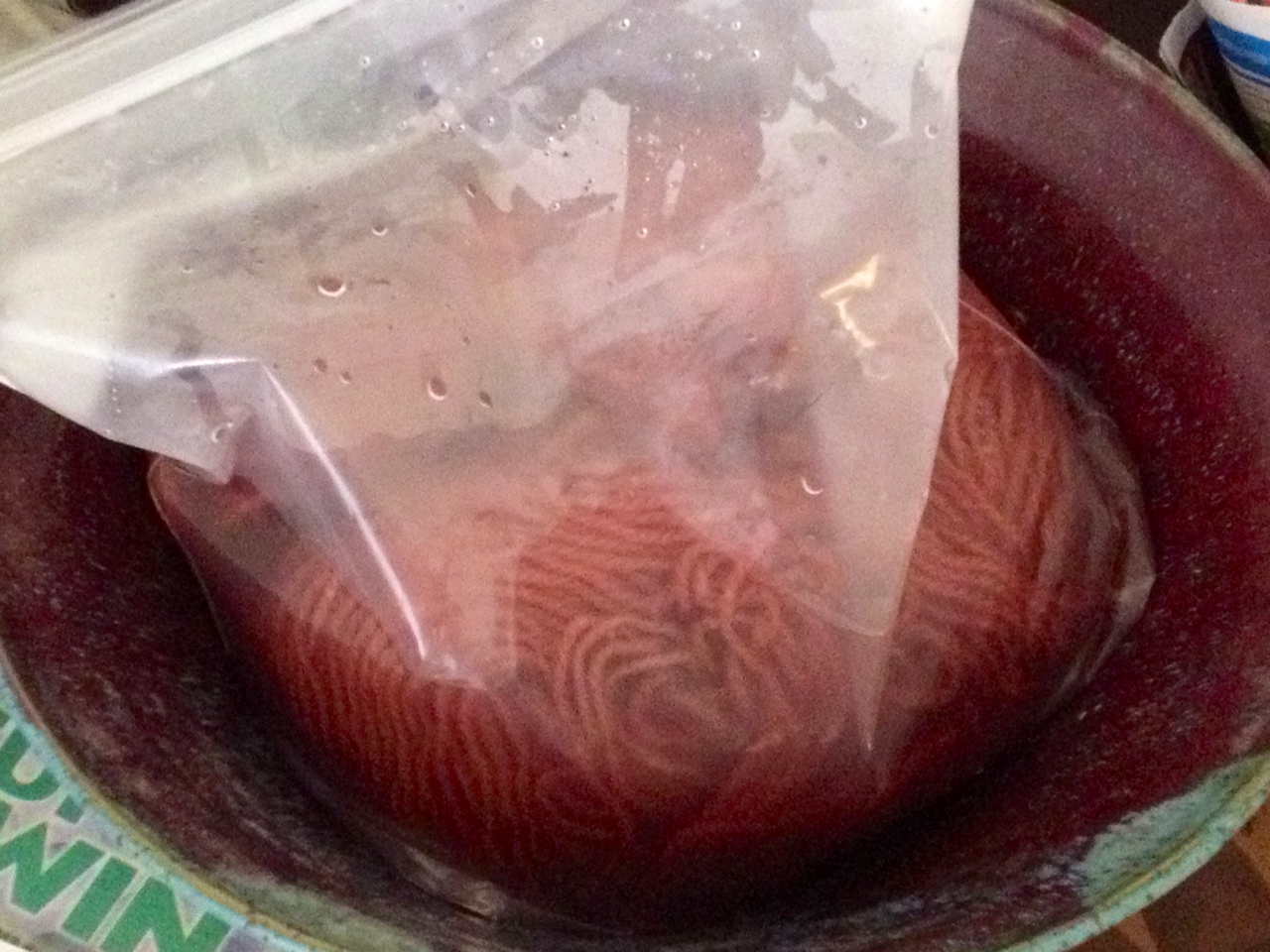

The materials: The most common types of 3D printer filament are ABS (made famous by Legos), PLA (corn plastic), nylons, and wood. (“Wait, wood?” you say? It’s not 100% wood, it’s wood pulp bound together by PLA.) ABS and PLA come in several colors; nylon is just one color, but as I discussed last week, it can be dyed! For all of your shopping-on-the-couch-in-your-skivvies needs, Amazon now has its very own 3D Printer Store with a huge filament selection, as well as some 3D printers and parts.

Want something made but don’t own a printer? Shapeways will print it for you. If you’re a student, some engineering schools may also have 3D printers available for use (in my hometown, the University of Wisconsin-Madison has a student print shop in their College of Engineering, though it’s fairly costly). And if the reverse is true, and you own a printer but would rather use someone else’s designs? Thingiverse lets people share all things 3D that they’ve designed, so while you can upload your own creations there, you can also grab other users’ files and print them.

There are several ways to get your feet wet without having to buy a 3D printer right away. Find out if there’s a makerspace or hackerspace in your area -- most will usually have at least one 3D printer, and they may even offer classes. That’s how I first learned about 3D printing. (Makerspace.com has a makerspace directory, although it appears to still be a work in progress.) It’s also worth looking for a nearby Maker Faire, where 3D printing always features prominently. There are half a dozen flagship Maker Faires each year, but in addition to those, there are a ton of smaller, regional Faires. Come for the robots, stay for the Makerbots.

For further reading, Make magazine, the quarterly bible of the maker movement, has an Ultimate Guide to 3D Printing.

While I’ve barely scratched the surface of the resources out there, you can do some pretty cool things with even remedial knowledge of 3D printing, so I hope this has been a useful jumping off point if you’re new to it. Go forth and print!